UNSURPASSED AUTOMATION

Mitsubishi Laser Automation

Boost Your Productivity with Mitsubishi Laser Automation

Are you looking to take your metal fabrication business to new heights? Look no further than Mitsubishi Laser Automation. As a leader in laser technology, Mitsubishi offers a comprehensive range of automation solutions that are designed to streamline your operations, enhance productivity, and maximize profitability.

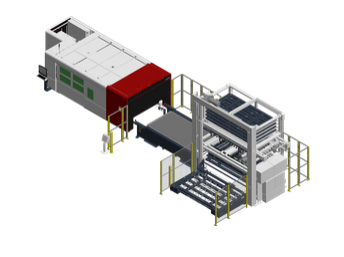

Smartflex Element Type R

If floor space is a hot commodity at your shop, and you are looking to achieve the maximum throughput, can you still access all the benefits of industrial automation?

We have some good news. The answer is yes, and the SmartFlex ELEMENT is here to back us up.

The SmartFlex ELEMENT is a quick and efficient material loading and unloading system. But its small footprint combined with its ability to work in fully lights-out situations makes it a pocket-sized productivity powerhouse. Sometimes the best things in life really do come in small packages.

Smartflex Compact Plus

The SmartFlex COMPACT series provides flexible, expandable automation into a compact footprint. With an installation footprint of less than 32’x42’ (3015), the SmartFlex COMPACT is a purpose-built load/unload unit for maximum productivity in minimum space.

This space-saving design comes in a number of configurations, making automation possible. Plus, today’s software capabilities and cycle times make even short-run job shop environments good candidates for automation.

Smartflex Rapid Base

Highly configurable and expandable, the RAPID keeps everything moving quickly and efficiently well into the future.

A good automation system is one of the most effective ways for any machine shop to reliably send more finished products out the door than ever before. With an industry-leading 52-second (3015) load/unload cycle time, this machine is quick. That’s why we named this automated sheet loader, the SmartFlex RAPID.

With intelligent, fully independent load and unload units that can easily support up to four lasers on the same line, and with dual-automated SmartStation carts for both load and unload—each capable of supporting 11,000 lbs. of raw material or finished goods—the SmartFlex RAPID is as powerful and versatile as it is fast.

Smartflex Rapid Tower

With an industry-leading 52-second (3015) load/unload cycle time, this machine is quick. That’s why we named this automated sheet loader, the SmartFlex RAPID.

With intelligent, fully independent load and unload units that can easily support up to four lasers on the same line, and with dual-automated SmartStation carts for both load and unload—each capable of supporting 11,000 lbs. of raw material or finished goods—the SmartFlex RAPID is as powerful and versatile as it is fast.

SmartFlex RAPID packs all the punch you need to make your dreams of quick, reliable, cost-efficient production a reality.

Our RAPID Tower maintains all of the advanced features and speed of our RAPID Base with the added ability to store an incredible amount of raw material with a standard 8 shelves. It can be configured with as many as 46 shelves with multiple towers and can be serviced by up to 3 lasers on a single line.

Smartflex River System

An automated system designed to maximize workflow efficiency and to minimize labor, the SmartFlex RIVER delivers material-handling and inventory-tracking solutions for shops of all sizes and needs by providing virtually unlimited storage and machine capability.

It can automate the setup of small lots, plan multiple product runs in a single shift, manage and coordinate processes that span the entire shop floor, and much more. Because, at the end of the day, what makes the SmartFlex RIVER unique has everything to do with flexibility.

Start small or go big—the uses for this modular, multipurpose machine is limited only by your requirements and imagination.

Astes 4 Sorting System

Capable of controlling the entire production process—from loading, cutting, sorting, and unloading through to the storage of the finished parts—the ASTES4 SORT is the process-optimizing, throughput-boosting, performance-focused lynchpin of any laser automation system.

Here’s how it works.

All loading, unloading, and sorting processes are controlled by four cartesian grippers. After the parts have been laser cut, the cartesian grippers independently pick out the assigned parts. The parts are then sorted on pallets. The pallets can be stored in the warehouse, awaiting pickup and shipment. Scraps are then removed and placed in scrap removal forks or conveyors. This entire process is known as “lasorting.”

Where some systems shoot for “hands-off,” the ASTES4 SORT is your chance to gain several extra hands—exactly where you need them.

Here are just a few reasons why Mitsubishi Laser Automation should be at the top of your list:

# 1. Cutting-Edge Technology

With Mitsubishi Laser Automation, you can harness the power of cutting-edge technology to optimize your production processes. Their advanced laser systems boast exceptional precision, speed, and versatility, allowing you to handle a wide range of materials and intricate designs with ease. Say goodbye to manual cutting and hello to automation that delivers consistent, high-quality results.

# 2. Enhanced Efficiency

By incorporating automation into your laser cutting operations, you can significantly enhance your efficiency. Mitsubishi's automation solutions enable seamless integration between multiple processes, such as loading, unloading, nesting, and inventory management. This eliminates labor-intensive tasks, reduces human error, and ultimately boosts your productivity levels.

# 3. Improved Safety

Mitsubishi prioritizes the safety of both your employees and equipment. Their automation solutions come equipped with advanced safety features, such as sensors and interlocks, ensuring that operations are conducted in a secure environment. With Mitsubishi's laser automation, you can have peace of mind knowing that you are investing in equipment that meets or exceeds industry safety standards.

# 4. Cost Savings

Investing in Mitsubishi Laser Automation means investing in long-term cost savings. By automating your processes, you can minimize labor costs, reduce material waste, and optimize your energy consumption. Additionally, Mitsubishi's automation solutions are built to withstand the test of time, resulting in decreased maintenance and repair expenses. You'll see a rapid return on your investment, leading to increased profitability.

# 5. Tailored Solutions

At Mitsubishi, they understand that every business has unique requirements. That's why they offer tailored automation solutions that can be customized to meet your specific needs. Whether you are a small shop or a large-scale manufacturing facility, Mitsubishi's team of experts will work closely with you to design a solution that maximizes your productivity and aligns with your goals.

# 6. Exceptional Service and Support

When you choose Mitsubishi Laser Automation, you gain access to their renowned service and support network. Their team of highly skilled technicians is available to assist you with installation, training, troubleshooting, and ongoing maintenance