PLASMA - OXYFUEL - BEVEL CUTTING - WATERJET

AKS Plasma & Waterjet Machines

AT THE FOREFRONT OF MACHINE DESIGN AND FABRICATION SINCE 1912

AKS Cutting Systems manufactures CNC cutting machines including plasma, oxy-fuel and waterjet systems for the sheet metal and plate metal and fabricating industries. The company has a strong reputation for durability, accuracy, and reliability with thousands of installations worldwide.

AKS Plasma Machines: Revolutionizing Metal Fabrication

When it comes to metal fabrication machinery, AKS Plasma Machines stand out as top contenders in the industry. With their cutting-edge technology and efficient performance, these machines are revolutionizing the way metal fabrication is done. AKS Plasma Machines boast state-of-the-art plasma cutting systems that deliver precise and clean cuts, allowing for enhanced accuracy and productivity. Equipped with robust and durable components, these machines are built to withstand the toughest of metal cutting tasks, ensuring long-lasting performance and minimal downtime. What sets AKS Plasma Machines apart is their user-friendly interface, which makes operation seamless and intuitive, even for beginners. Whether it's for small-scale projects or large-scale industrial applications, AKS Plasma Machines deliver unmatched versatility, making them a reliable choice for businesses in the metal fabrication industry.

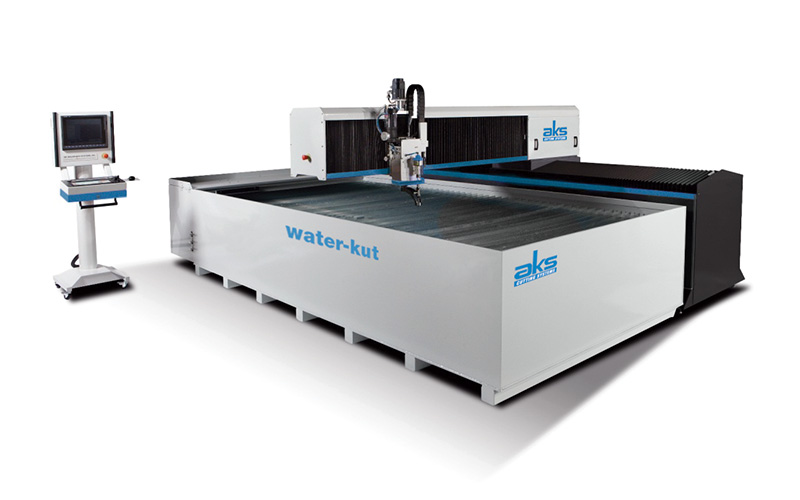

X-2 Waterjet

5’ x 10’ or 6 ’x 12’ work envelope designed for shops requiring a heavy-duty, unitized waterjet

Standard water table with optional submerged cutting feature and 6″ thick plate capacity.

Tube-Kut

The tube-kut add-on system for accu-kut and dura-kut increases processing flexibility while saving space and capital investment vs. dedicated pipe & tube cutting systems.

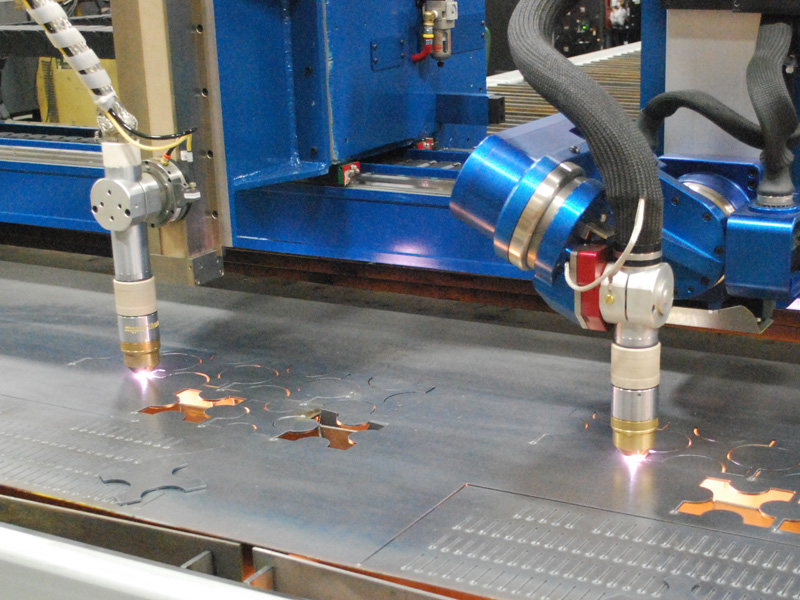

robo-kut

5-axis bevel head for weld prep applications, contour beveling, and precision small holes

The robo-kut is add-on for dura-kut and accu-kut plasma cutting machines. The robo-kut is able to bevel up to +/- 45 degrees with unlimited winding, offering superior contour beveling in A, V, X, Y and K cutting operations, and precision bolt hole cutting.